F10 Straight

Plastic Axle Housing

Partial Assembly

1- Drill the 1/8” bit through the blind pocket on the truss front. The hole is slightly tapered and will self-center.

2- Use the chamfer bit to taper the backside of the newly drilled hole. Only go deep enough to bury the flat screw head

3- Place Skid onto front of axle. Place Button head screw with RIGHT MOUNT ADAPTER correctly oriented so it matches the contours of the back side of the truss and axle, use M2 hex driver to tighten the bolt by hand. It will snug up. Do not over tighten! Place the flat head screw on the left and tighten by hand until snug.

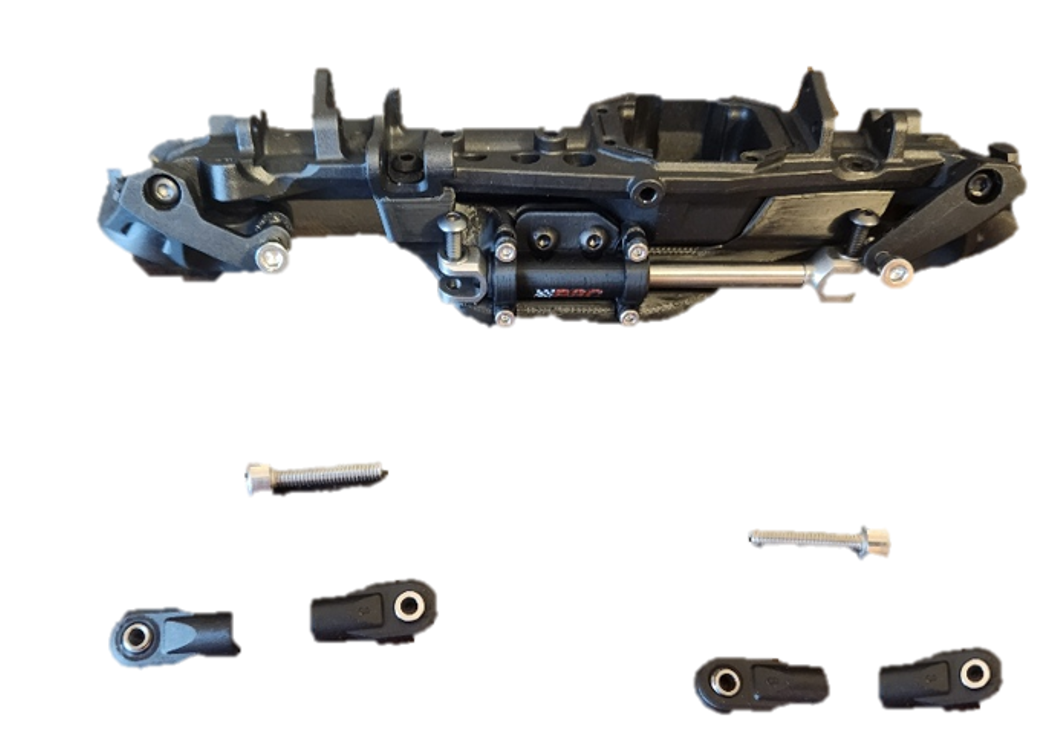

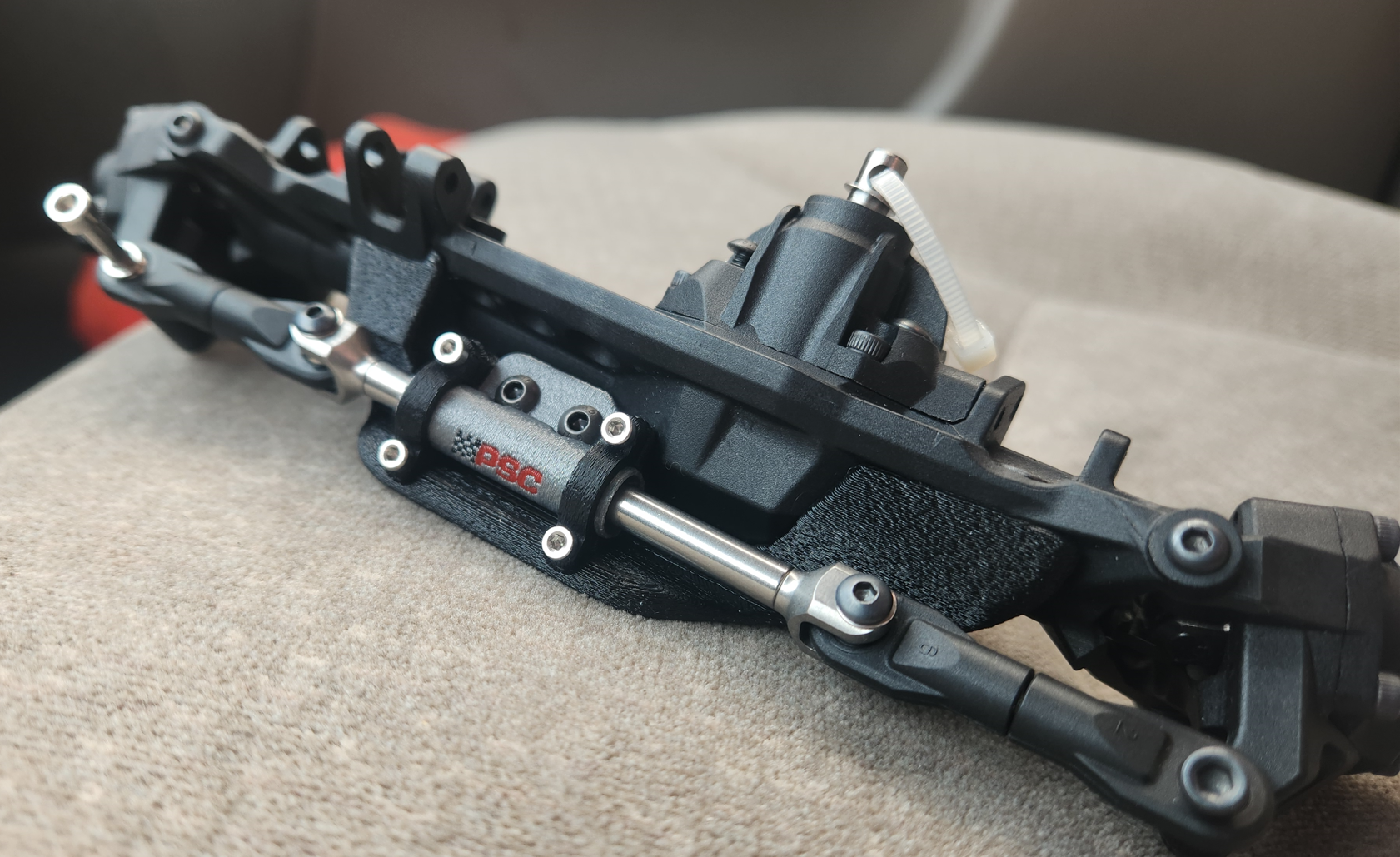

Full Assembly with Steering Ram kit:

4- To assemble the short steering links, take 4 standard Incision end links, insert the supplied pillow balls from the Steering Kit. I took a M4x20mm stud, if you don’t have one you can use a M4x20mm SHCS and used a cutoff wheel to remove the head and use the remaining 18mm-19mm stud length to join the end links together. Slide the ram through the printed cylinder, bolt on yokes supplied in the Incision kit and install the short linkages. This setup is a high steer, and is mounted on the top of the knuckle. Place the links to the topmost surface of the Knuckle, place a spacer where the old linkage would have gone. I would use a M3X30mm for the servo linkage side and a make sure the bolts that hold the linkage through the ram are facing up to clear the skid plate. The H10 links in the Incision kit do not work, they are too long.